The steering system is an essential part of the normal operation of a car. It is a complex overall system consisting of three subparts: steering mechanism, steering rack, and steering transmission mechanism, of which the structure of the steering gear is the most complex among the three and is inseparable from the final characteristics of the steering system.

The steering gear is the most important part of the steering system to realize the function of the steering system by changing the angle of rotation generated by the driver’s steering wheel into the angle of deflection of the car wheels through a series of mechanical transmissions structures.

There are two main types of steering gears used in modern automobiles: rack and pinion steering gears and recirculating ball steering gears. The recirculating ball steering gears are widely used in trucks, so this article mainly introduces the structural components and performance characteristics of the recirculating ball steering gears, and the rack and pinion type is slightly understood.

1 Structure principle of the recirculating ball steering rack

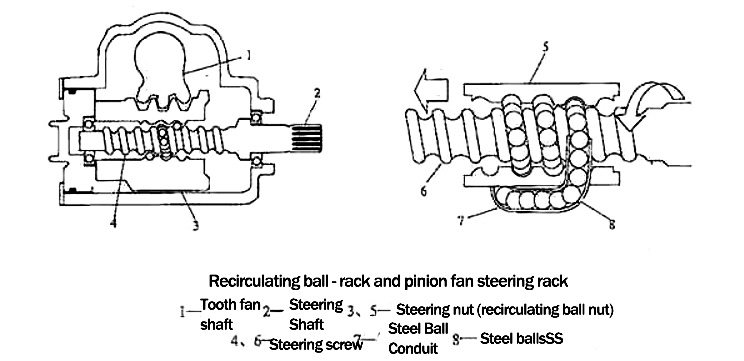

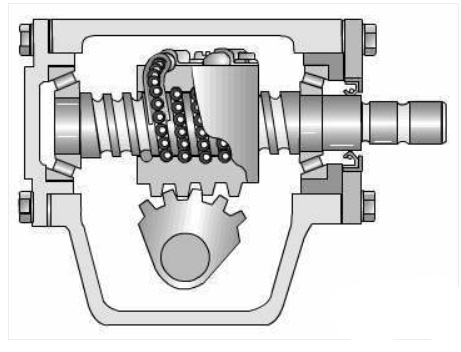

Circulating ball steering gear has two transmission subsets, the first one is the steering screw and the steering nut, where the steering ball is sandwiched between the two formed tracks so that the steering screw and the nut do not directly contact each other, mainly to reduce friction and smooth transmission.

In order to let the steel ball has been between the two steering nut is also equipped with a steel ball conduit so that the extended threads rolled out of the steel ball back to the screw and nut between the formation of the track.

The secondary drive sub is the rack and fan, the rack is machined on the lower surface of the steering nut, so turning the steering wheel makes the steering nut move, and the steering nut turns its own linear motion into an output angle by cooperating with the fan, the fan, and the fan shaft are one structure, and the steering cross lever is driven by the fan shaft to achieve wheel steering.

2 Performance Features

Because its structure is mainly rolling friction, the transmission efficiency is very high, also because this feature of low friction makes the cycle ball-type steering long life and good reliability, for heavy load trucks this is a great advantage.

Of course, it also has its own disadvantages, the sensitivity of the rack and pinion steering machine is worse, for the pursuit of handling models generally do not use it, there is it’s not only high forward transmission efficiency reverse efficiency is also very high, which causes the wheels affected by uneven road easily back to the steering wheel to produce the phenomenon of hand.

But with the addition of hydraulic power, this feature is no longer considered a disadvantage.

3 Rack and pinion type

The main structure is composed of steering gear and steering rack, plus the shell and preload adjusting device and other accessories and support parts, the structure is relatively simple. In principle, the gears at the top and bottom of the steering shaft directly push the rack to move left and right, and the rack is connected to the steering lever to realize the steering action.

The rack and pinion type have high sensitivity, simple structure, and low cost, and it is easy to arrange the power assist system, so it is a very suitable structure for passenger cars.

4 Conclusion

With the increasing level of vehicle electrification, more advanced technologies such as wire-controlled steering may also be applied to trucks, but in terms of the current level of technology and usage effect, the traditional mechanically driven recirculating ball steering is still the most suitable choice for medium and heavy trucks.

(We do not share your data with anybody, and only use it for its intended purpose)

The Previous Articles:

What Is Rack and Pinion Bushing? How To Tell If Rack and Pinion Bushings Are Bad?

Why Steering Rack Makes Noise When Turning?

How To Rebuild A Steering Rack?

What Is A Rotary Valve Power Steering Rack?

Rack And Pinion System Vs Power Steering System: What Are The Differences?

Power Steering Rack Market Analysis Report (Japan Market)

What Causes Steering Rack to Go Bad?

Design Of Car Rack And Pinion Steering Racks

What Is The Intelligent Steering Rack Used By VW, Toyota, Honda And Renault?

Leave A Comment