With the rapid development of our automobile industry in recent years, the production level of automobile steering gear, an important safety component of automobiles, has also been greatly improved. In the automobile steering production industry, the circulating ball steering was promoted in the 70s, and the circulating ball variable-ratio steering rack was developed and promoted in the 80s, and in the 90s, the driver's requirements for the performance of the automobile steering rack were further improved, requiring lighter steering and more sensitive maneuvering.

With the generalization of high-speed ratio and ultra-low-pressure flat tires, the past use of recirculating ball steering gear and recirculating ball variable transmission ratio steering can only relatively solve the problem of steering lightness and maneuvering sensitivity, now although the steering to power steering development, most of the cars still apply mechanical type steering, how to improve the design of the steering to make it more suitable for the driver is the most important, so there is a need for continuous improvement.

1 Design initial design parameters and requirements

Initial parameters

- Steering wheel unilateral turning angle ≤180°.

- Steering wheel diameter ≤250mm.

- Steering system angle transmission ratio 4:1 to 5:1

- Maximum steering wheel force ≤100N.

The design requirements of the steering system

(1) To ensure that the car has high maneuverability, the ability to turn quickly and within a small radius within a limited site area while operating lightly;

(2) When the car is steered, all wheels should rotate around an instantaneous steering center, and there should be no side slip;

(3) The backlash transmitted to the steering wheel should be as small as possible;

(4) After steering, the steering wheel should automatically return to the right, and should keep the car in a stable and straight driving condition;

(5) In case of a car accident, when the steering wheel and steering shaft move back together due to frame and body deformation, the steering system should have a protection mechanism to prevent injuries to the occupants.

2 Steering gear selection

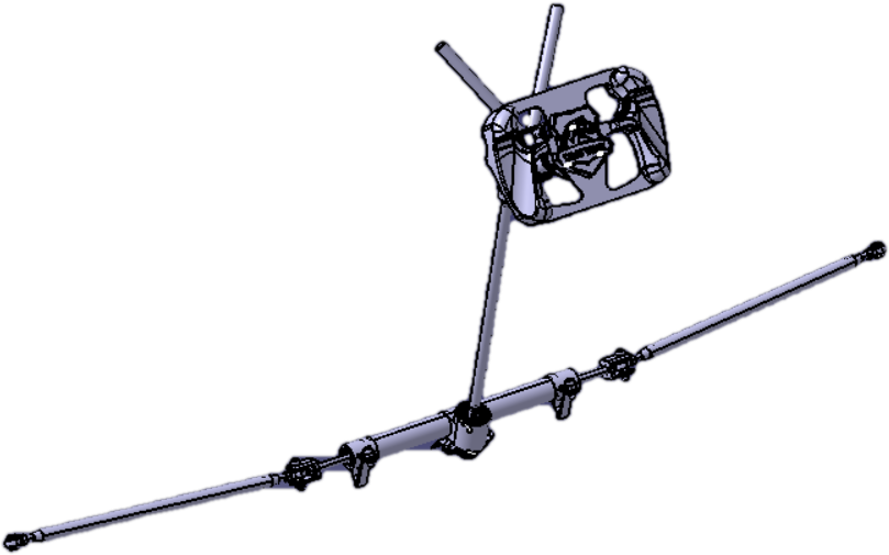

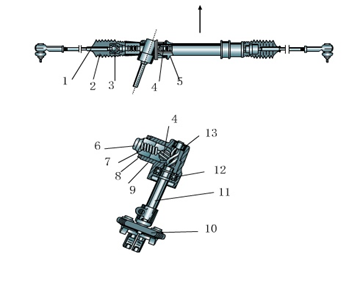

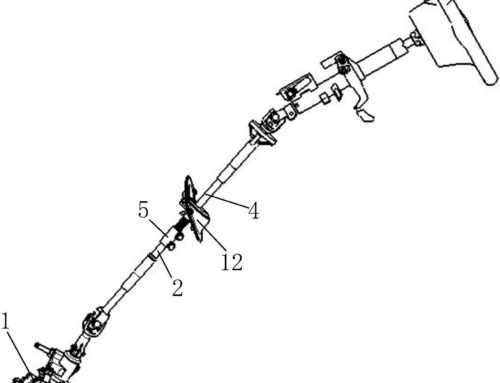

1) Rack and pinion steering rack

1. steering cross tie-rod 2. dust sleeve 3. ball head seat 4. steering rack 5. steering gear housing 6. adjusting screw 7. compression spring 8. lock nut 9. pressure block 10. universal joint 11. steering gear shaft 12. radial ball bearing 13. needle roller bearing

The main advantages of rack and pinion steering gear.

Simple, compact, small size, and lightweight; 90% high transmission efficiency; automatic elimination of inter-tooth clearance; no steering rocker and straight tie rod, steering wheel angle can be increased; low manufacturing cost.

The main disadvantages of rack and pinion steering gears.

High reverse efficiency (60%~70%). Therefore, when the car is driven on an uneven road, most of the impact force that occurs between the steering wheel and the road can be transmitted to the steering wheel.

Rack and pinion steering gears are widely used in micro, normal, intermediate, and mid-range cars. Rack and pinion steering gears are also used in trucks and buses with low load capacity and independent suspension at the front wheels.

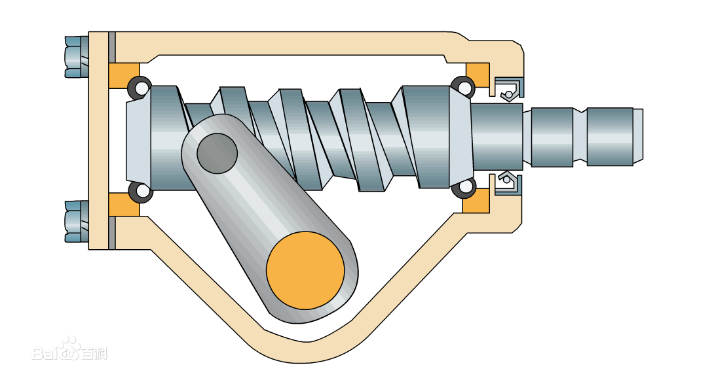

2) Worm gear crank pin steering gear

The worm gear crank pin steering gear has the worm gear as the active part and the crank pin as the follower.

The worm has a trapezoidal thread, and the finger-shaped tapered finger pin is supported by a bearing on the crank, and the crank is made integral with the steering rocker shaft. When steering, the worm is rotated by the steering wheel, and the conical finger pin embedded in the spiral groove of the worm rotates itself while making a circular motion around the steering rocker shaft, thus driving the crank and the steering arm to swing, and then deflecting the steering wheel through the steering transmission mechanism. This kind of steering gear is usually used in vehicles with large steering force.

There are two forms of worm finger pin steering, fixed pin type, and rotary pin type. Depending on the number of pins, there are also single and double pins.

Advantages of worm gear crank pin steering gears

The transmission ratio can be made constant or variable; easy to adjust the working surface clearance. The structure of fixed pin steering gear is simple and easy to manufacture.

Disadvantages of worm gear crank pin steering racks

The working part of the pin wears quickly and the efficiency is low. Rotary pin-type steering gear has high efficiency and slow wear, but the structure is complicated. A double pin type structure should be used when a large turning angle of the rocker arm shaft is required. Double pin type steering gear has a complex structure, large size, and mass, and requires high accuracy of position between two main pins, shape and size accuracy of thread groove, etc.

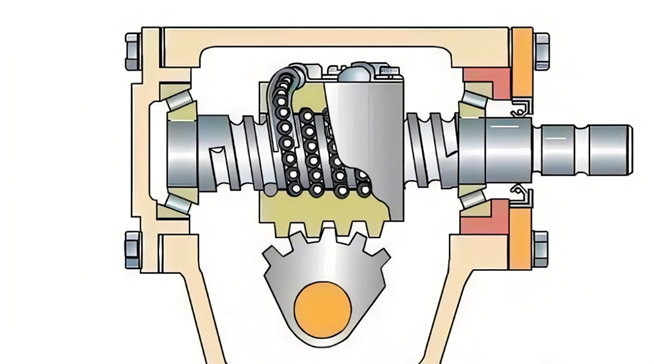

3) Recirculating ball steering gear

The recirculating ball steering gear consists of a driving pair consisting of a steel ball in a spiral groove formed by a screw and a nut, and a driving pair consisting of a rack on the nut and a tooth fan on the rocker arm shaft.

Advantages of recirculating ball steering gear

Between the screw and the nut, the sliding friction becomes rolling friction because of the steel ball that can circulate, so the transmission efficiency can reach 75%-85%; after taking measures in the structure and process, including improving the manufacturing accuracy, improving the surface roughness of the working surface and the spiral groove on the nut and screw by quenching and grinding, so that it has sufficient hardness and wear resistance. The performance can ensure sufficient service life; the ratio of the steering system can be changed; the adjustment of the clearance between the rack and the fan is easy; it is suitable for the integral power steering.

Disadvantages of recirculating ball steering gears

With the development of the times and the application of steering power technology, the rack, and pinion structure is simpler and more conducive to the installation of power-assist devices, so the future of the circulating ball steering is slim.

From the above analysis, and the design initial conditions, it can be determined that the design formula racing car adopts a reversible rack and pinion steering mechanism. And because the whole racing car is relatively light in mass, there is no need to use a power steering device. This kind of steering mechanism is compact, small in size, light in mass, and good in road feel, which is very suitable for the steering requirements of a formula racing car.

(We do not share your data with anybody, and only use it for its intended purpose)

The Previous Articles:

What Is Rack and Pinion Bushing? How To Tell If Rack and Pinion Bushings Are Bad?

Why Steering Rack Makes Noise When Turning?

How To Rebuild A Steering Rack?

What Is A Rotary Valve Power Steering Rack?

Rack And Pinion System Vs Power Steering System: What Are The Differences?

Power Steering Rack Market Analysis Report (Japan Market)

What Causes Steering Rack to Go Bad?

Design Of Car Rack And Pinion Steering Racks

What Is The Intelligent Steering Rack Used By VW, Toyota, Honda And Renault?

Leave A Comment