If you are a regular car owner, there's a good chance that you may not know what hydraulic steering is.

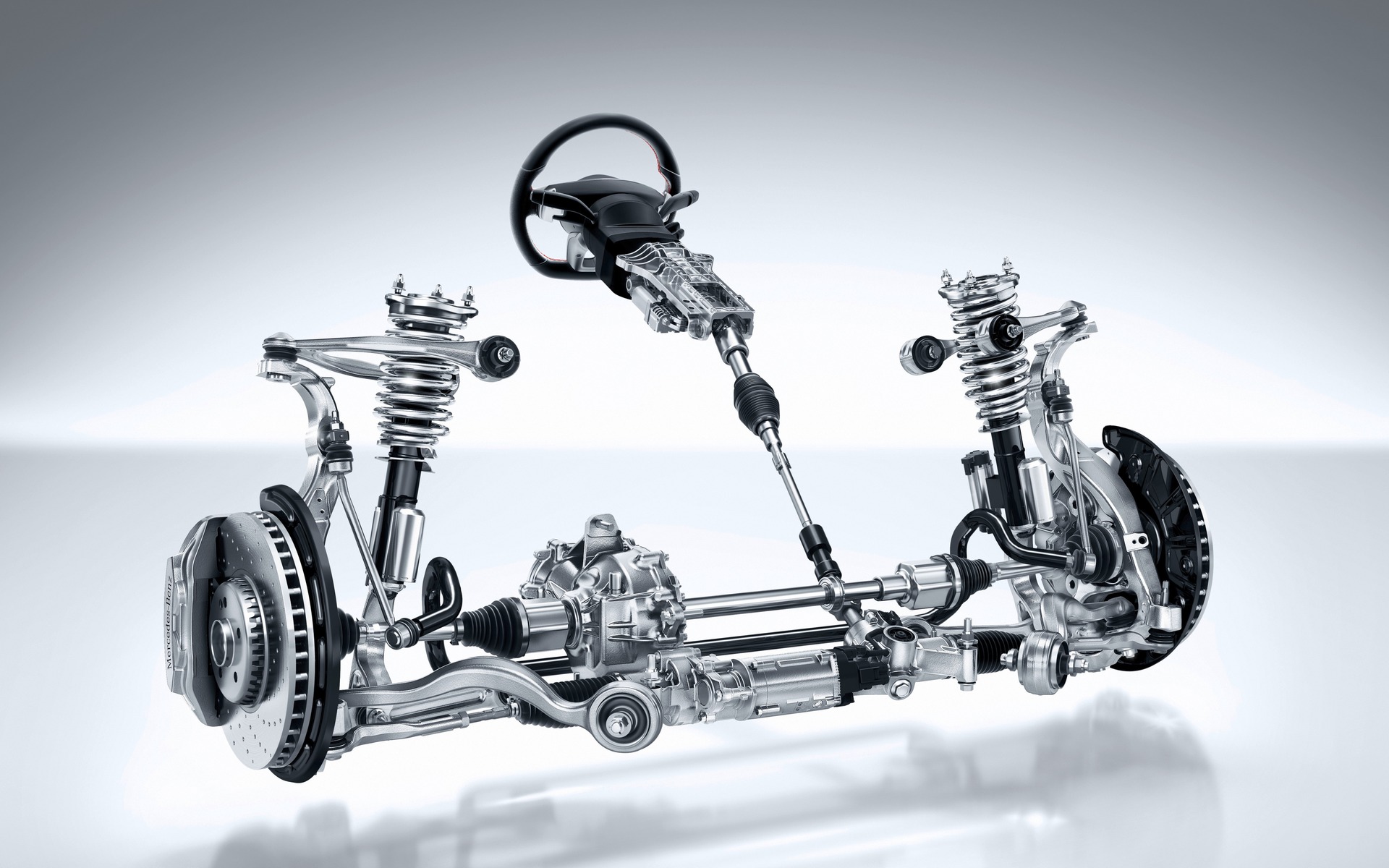

A hydraulic steering rack is a component of your car's steering system that helps steer the car. It replaces the traditional mechanical linkage with a series of hydraulic cylinders and hoses.

If your car has a power steering system, it likely has a hydraulic steering system.

While they are more common in newer cars, older cars can also benefit from installing a hydraulic steering system. If you're considering getting one for your car, here's what you need to know.

1 What is a Hydraulic Steering Rack?

A hydraulic steering rack is responsible for translating the driver's input into hydraulic pressure. This pressure is then used to move the vehicle's wheels in the desired direction.

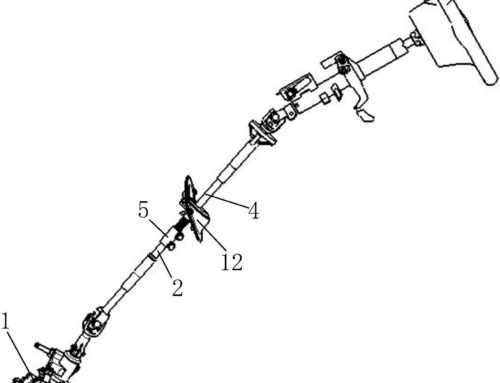

The hydraulic steering system consists of several components, including a pump, reservoir, valves, and hoses. The pump is used to generate hydraulic pressure, which is then directed to the appropriate valve.

The valve regulates the flow of hydraulic fluid and directs it to the appropriate hose. The hoses are responsible for carrying the hydraulic fluid to the vehicle's wheels.

The entire system is typically located in the engine bay, just behind the vehicle's front bumper.

2 History of Hydraulic Power Steering

In 1876, George Westinghouse patented a hydraulic power steering system for use on locomotives. His design used a fluid-filled cylinder to provide resistance to the turning force of the locomotive's wheels.

However, it was not until the 1950s that hydraulic power steering racks began to be used in automobiles.

The first such system was introduced by Chrysler in 1951, and it quickly became standard equipment on many American cars.

Today, hydraulic power steering systems are found on vehicles all over the world. Though they have undergone many changes over the years, they continue to provide drivers with a smooth, comfortable steering experience.

Thanks to George Westinghouse's early invention, we enjoy safe, reliable steering on our cars and trucks today.

3 How Does Hydraulic Power Steering Work?

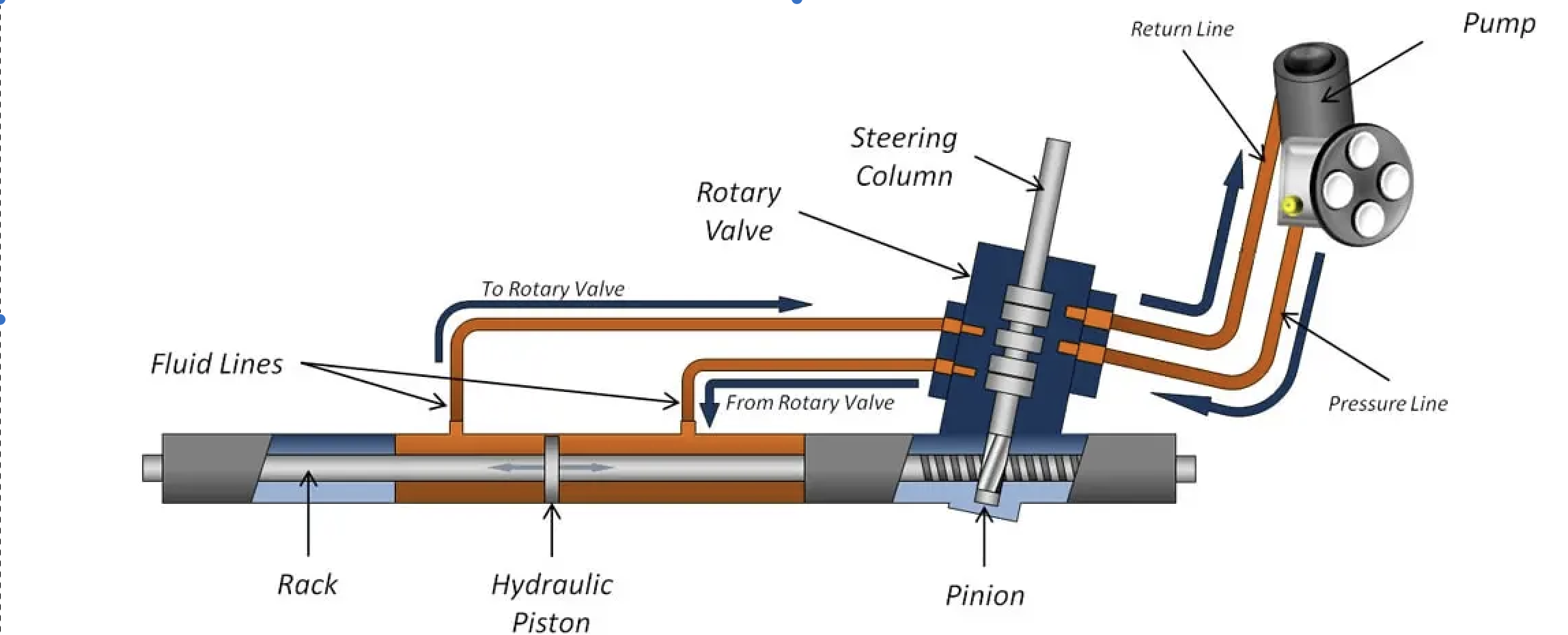

Hydraulic power steering uses fluid to help turn the wheels of a vehicle. The system consists of a pump, fluid lines, and a rack and pinion assembly.

The pump is usually powered by the engine belts and draws the fluid from a reservoir. The fluid then flows through the lines to the rack and pinion assembly, where it assists in turning the wheels.

When the vehicle is not in motion, the fluid is redirected back to the reservoir by a valve.

A hydraulic power steering rack is used in many modern vehicles and helps to provide a smoother, more controlled driving experience.

It also requires less effort to turn the steering wheel, which can be especially helpful when maneuvering at low speeds or parking.

4 Special Components of a Hydraulic Power Steering

Hydraulic power steering systems are typically found on larger vehicles, such as trucks and buses. They are not as common on smaller vehicles, such as cars, because they are more expensive and require more maintenance than other types of steering systems.

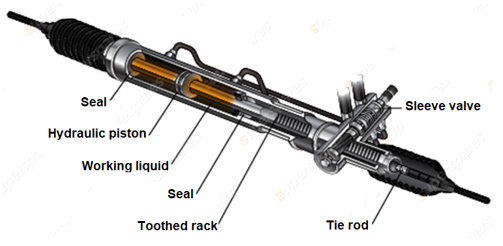

Unlike other types of power steering, hydraulic power steering has a couple of unique parts. These parts include a hydraulic chamber, rotary valve, steering pump, steering fluid reservoir, and hydraulic fluid.

These components work together to ensure the smooth and safe operation of the car.

1) Hydraulic Chamber

A hydraulic chamber is a cylindrical chamber that contains a gas or liquid under pressure. The pressure in the chamber is used to power hydraulic devices such as pumps and cylinders.

Hydraulic chambers are often used in construction and manufacturing applications where high levels of force are required.

For example, a hydraulic chamber can be used to power a ram that is used to push heavy objects.

Hydraulic chambers are also used in some automobiles, where they are used to power brakes and steering systems.

2) Rotary Valve

A rotary valve is a type of valve that is used in hydraulic steering systems. The purpose of the rotary valve is to route fluid from the steering pump to the steering gear.

The rotary valve is controlled by the steering wheel and allows the driver to control the amount of fluid that is sent to the steering gear.

The rotary valve is a critical component of the hydraulic steering system and helps to ensure that the vehicle can be steered safely and accurately. Without it, the hydraulic steering system would not be able to function properly.

That is why most car owners immediately buy a rotary valve from a steering rack supplier if they have a faulty rotary valve.

3) Steering Pump

The steering pump is the heart of the hydraulic steering system. It is a self-contained unit that contains a pump, reservoir, and steering valve all in one housing.

The steering pump is designed to produce high-pressure hydraulic fluid that is used to turn the wheels of the vehicle.

The reservoir on the steering pump holds a supply of hydraulic fluid that is used to replenish the fluid that is lost during operation.

The steering valve controls the flow of hydraulic fluid to the steering system. The pump is powered by a belt that is connected to the engine.

As the engine turns, the belt turns the pump, which produces hydraulic pressure. The amount of pressure produced by the pump determines how much force is required to turn the wheels.

4) Steering Fluid Reservoir

The primary purpose of a steering fluid reservoir is to store hydraulic steering fluid in a safe, accessible location. The reservoir is typically located near the steering pump and is connected to the pump via a hydraulic line.

When the steering wheel is turned, the steering fluid is pumped from the reservoir and into the steering system, where it helps to move the wheels.

Without a steering fluid reservoir, the hydraulic steering system would not be able to function properly. In addition to storing hydraulic fluid, the reservoir also helps to keep the fluid clean and free of debris.

This is important because contaminants in the fluid can damage the pump or other components in the system.

The reservoir typically has a filter that helps to remove any dirt or debris that might be present in the fluid.

By keeping the fluid clean and free of contaminants, the reservoir helps to extend the life of the hydraulic steering system.

5) Hydraulic Fluid

The purpose of hydraulic fluid is to transfer force within the system. In a car, this would be the power steering.

The hydraulic steering uses the force of the fluid to assist in turning the wheels. The hydraulic fluid is compressible, which allows it to change direction easily.

This is why it is used in power steering systems; it can easily change direction when the steering wheel is turned. Hydraulic fluids are also used in other systems, such as brakes, suspensions, and transmissions.

5 Advantages of Hydraulic Power Steering

If you're like most drivers, you probably take your car's power steering for granted. You turn the wheel, and it goes where you want it to. But what if your car didn't have power steering?

It would be a lot harder to turn the wheel, especially at low speeds. That's why almost all cars today come with hydraulic power steering - it makes driving much easier.

But what is hydraulic power steering, and why do some car manufacturers prefer installing them in their cars? Well, there are several advantages you need to know. This includes:

1) Offers Excellent Feedback

When it comes to steering feel, few systems can match the performance of hydraulic power steering. Unlike electric power steering, which can sometimes feel artificial and disconnected, hydraulic power steering provides excellent feedback to the driver.

This is due to the fact that hydraulic power steering is directly connected to the wheels via a series of hoses and valves. As a result, the driver has a direct sense of what the wheels are doing and can make corrections accordingly.

In addition, hydraulic power steering is generally more responsive than electric power steering, giving the driver greater control over the vehicle.

For these reasons, hydraulic power steering is often considered the best option for performance applications.

2) Cheaper Than Electric Power Steering

Hydraulic power steering is a type of steering assist that uses hydraulic fluid to help turn the wheels. Electric power steering, on the other hand, uses an electric motor to provide assistance.

Hydraulic power steering is typically cheaper than electric power steering, both in terms of initial cost and maintenance.

Electric power steering may offer a smoother ride and better fuel economy, but it's important to consider the tradeoffs when choosing between the two types of power steering.

3) More Reliable

Hydraulic power steering is more reliable than electric power steering for a number of reasons. First, hydraulic power steering is less likely to fail because it does not rely on electronic components that can fail.

Second, hydraulic power steering is more adjustable, so it can be tuned to the specific needs of the vehicle.

Third, hydraulic power steering is less expensive to repair than electric power steering. Finally, hydraulic power steering provides a smoother and more comfortable ride.

For these reasons, hydraulic power steering is the clear choice for reliability and performance.

6 Disadvantages of Hydraulic Power Steering

Not all systems are perfect. This includes hydraulic power steering systems. Even though it has tons of advantages, these systems also have a couple of disadvantages you need to consider.

1) Consumes More Power

Hydraulic power steering is a popular choice for many modern vehicles, but it does have some disadvantages.

One of the main drawbacks is that it consumes more power than other steering systems. This can lead to lower fuel economy and increased emissions.

Additionally, hydraulic power steering can be less reliable than other types of steering, especially in extreme conditions. If a hydraulic pump fails, it can cause the steering to fail entirely.

For these reasons, some drivers prefer to stick with traditional power steering.

2) Need to Regularly Replace Hydraulic Fluid

Hydraulic power steering is a system that uses fluid to assist in steering a vehicle. While this system offers a number of advantages, one of the main disadvantages is that hydraulic fluid needs to be regularly replaced.

This can be a costly and time-consuming process, and it is important to make sure that the fluid levels are kept topped up in order to prevent damage to the system.

In addition, hydraulic power steering can sometimes leak fluid, which can be messy and difficult to clean up.

Overall, while hydraulic power steering has many benefits, it is important to be aware of the potential drawbacks before making a decision about whether or not to use this type of system in your vehicle.

3) It Has a Complicated Steering System

Though hydraulic power steering systems are considered more efficient than older, belt-driven models, they do have some disadvantages.

One of the biggest is that they are much more complicated, meaning that there are more opportunities for something to go wrong.

In addition, hydraulic power steering systems require a steady supply of hydraulic fluid, which can leak if there is a problem with the system.

As a result, hydraulic power steering systems require more maintenance than other types of steering systems.

Another potential disadvantage is that hydraulic power steering systems can make it difficult to turn the wheel when the engine is off, making it difficult to park or maneuver in tight spaces.

However, this can be alleviated by adding a power steering pump bypass valve.

Overall, hydraulic power steering systems have both advantages and disadvantages, but it is important to weigh all factors before making a decision.

7 Which is Better – Hydraulic or Electric Power Steering System?

Hydraulic power steering systems have been the standard for many years, but Electric Power Steering (EPS) is becoming more popular in newer vehicles. So, which system is better?

That really depends on your needs and preferences. Hydraulic power steering uses fluid pressure to assist in turning the wheels, while EPS uses an electric motor.

Each has its own advantages and disadvantages. For example, hydraulic power steering is typically more responsive than EPS, making it a good choice for performance vehicles.

However, EPS is more efficient, so it doesn't put as much strain on the engine. In addition, EPS is less likely to leak than hydraulic power steering, making it a good choice for those who want to avoid potential messes and repairs.

Ultimately, the best system for you will depend on your driving habits and preferences.

8 Common Issues with Hydraulic Power Steering

Most car owners know that there are some common problems with hydraulic power steering. But do you know what they are? Here are some of the most common issues with hydraulic power steering.

1) Fluid Leak

One common issue with hydraulic power steering is fluid leaks. These leaks can be caused by a variety of factors, including loose hoses, damaged seals, and wear and tear on components.

If left unchecked, fluid leaks can lead to a loss of steering power and increased steering effort. In extreme cases, it can even cause the steering to fail completely.

To prevent these issues, it is important to regularly check for fluid leaks and have them repaired as soon as possible.

2) Clog in the System

Hydraulic power steering systems have many moving parts that are all susceptible to wear and tear. Over time, these moving parts can become clogged with dirt and debris, making it difficult for the system to function properly.

As a result, the steering may feel heavy or stiff, and the vehicle may be difficult to steer. If this issue is not addressed, it can eventually lead to the complete failure of the power steering system.

3) Worn Pump

One common issue with hydraulic power steering is a worn pump. The pump is responsible for supplying fluid to the steering system, and over time, it can become less effective at doing so.

As a result, the steering may feel heavy or stiff, and the vehicle may be harder to turn. In some cases, the pump may also make noise when it is turned on or off.

If you notice any of these issues, it is important to have the pump checked by a mechanic.

A worn pump can often be replaced without too much difficulty, and doing so can help to restore the steering to its proper operation. You can purchase one from a steering rack supplier.

4) Air in The System

Another common issue with hydraulic power steering is air in the system. Air bubbles can form in the fluid, which can reduce its effectiveness.

As a result, the vehicle may be difficult to steer, or the steering may feel heavier than normal. To fix this problem, the air must be removed from the system.

This can be done by bleeding the fluid or by replacing the fluid entirely. Either way, it is important to fix the problem as soon as possible to avoid any damage to the steering system.

9 Conclusion

These are all the things you should know about hydraulic power steering. After reading this article, you should at least have a basic idea of how your car's steering works.

The Previous Articles: Steering rack Diagram What Is Rack and Pinion Bushing? How To Tell If Rack and Pinion Bushings Are Bad? Why Steering Rack Makes Noise When Turning? How To Rebuild A Steering Rack? What Is A Rotary Valve Power Steering Rack? Rack And Pinion System Vs Power Steering System: What Are The Differences? Power Steering Rack Market Analysis Report (Japan Market) What Causes Steering Rack to Go Bad? Design Of Car Rack And Pinion Steering Racks What Is The Intelligent Steering Rack Used By VW, Toyota, Honda And Renault?

Leave A Comment