The automotive industry has witnessed a remarkable evolution over the years, with technology constantly pushing the boundaries of what is possible. Among the many innovations in the field, the steering system has undergone significant changes to enhance safety, performance, and efficiency. One critical component within this system is the steering rack belt, specifically the electric steering rack belt. In this comprehensive guide, we will explore the significance of a steering rack belt, with a particular focus on electric steering rack belts, and understand how it has revolutionized the way we steer our vehicles.

Understanding the Basics: What is a Steering Rack Belt?

Before we delve into the specifics of electric steering rack belts, it is essential to grasp the fundamentals of a steering rack belt. This component is a vital part of a vehicle's steering system, responsible for converting the rotational motion of the steering wheel into linear motion, which turns the wheels and changes the vehicle's direction.

In traditional steering systems, a mechanical linkage, such as a set of gears, was used to connect the steering wheel to the front wheels. However, modern vehicles have largely transitioned to power-assisted steering systems for enhanced comfort and maneuverability. In such systems, a steering rack belt is a key component that plays a crucial role in the overall functionality of the steering system.

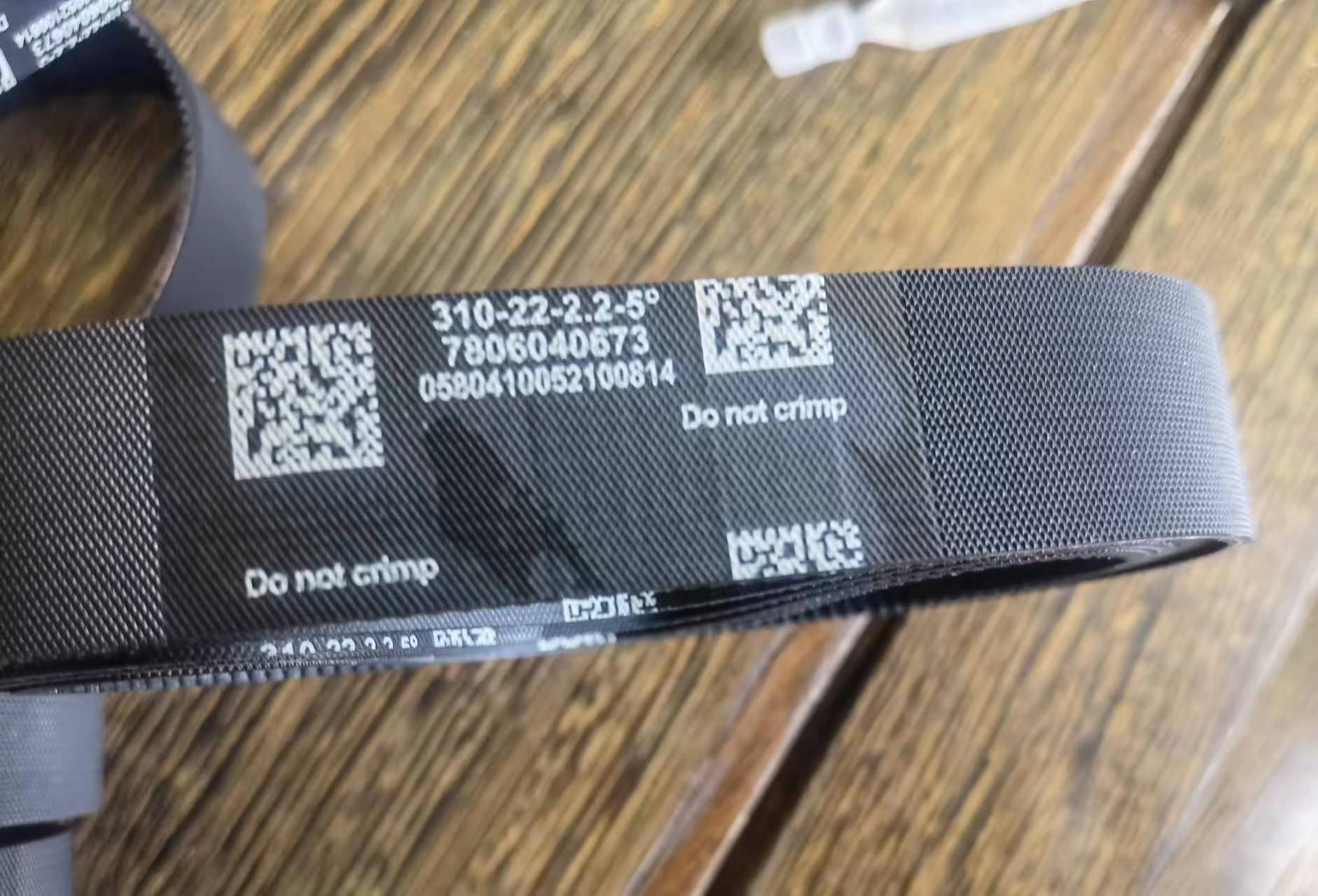

The steering rack belt is a flexible belt made of durable materials that connects the steering column to the steering rack. When you turn the steering wheel, the belt transfers the motion to the steering rack, which then moves the front wheels accordingly. This design allows for precise and efficient control of the vehicle's direction.

The Evolution: Introduction of Electric Steering Rack Belts

While traditional hydraulic power steering systems have been in use for decades, the automotive industry has recently witnessed a shift towards electric power steering (EPS) systems. Electric steering rack belts have been at the forefront of this transformation. EPS systems offer several advantages over their hydraulic counterparts, including improved fuel efficiency, reduced maintenance requirements, and enhanced adaptability.

Advantages of Electric Steering Rack Belts

- Fuel Efficiency: One of the primary advantages of electric steering rack belts is their ability to enhance fuel efficiency. Unlike hydraulic systems, electric systems only draw power from the engine when needed. This means that the engine does not continuously power a hydraulic pump, resulting in reduced energy consumption and improved fuel economy.

- Reduced Maintenance: Electric steering rack belts require less maintenance compared to hydraulic systems. Traditional hydraulic power steering systems rely on fluids that need periodic checks and replacements, while electric systems are generally more self-sufficient and less prone to leaks and fluid-related issues.

- Adaptability: Electric steering rack belts offer greater adaptability in terms of vehicle dynamics and driver preferences. Manufacturers can program the EPS system to provide various levels of assistance, allowing drivers to customize the steering feel, responsiveness, and feedback.

- Integration with Vehicle Systems: Electric steering rack belts can be easily integrated with other vehicle systems, such as advanced driver assistance systems (ADAS). This enables features like lane-keeping assist and automated parking, which rely on precise steering control.

- Environmental Benefits: The reduced energy consumption of electric power steering systems aligns with the automotive industry's broader goals of reducing carbon emissions and improving environmental sustainability.

How Electric Steering Rack Belts Work

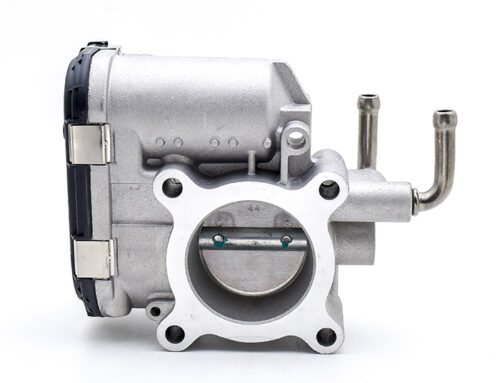

Electric steering rack belts function by utilizing an electric motor to assist in steering. When the driver turns the steering wheel, sensors detect the input and send signals to the electric motor. The motor then applies the necessary force to the steering rack belt, aiding in wheel movement. The amount of assistance provided can be adjusted according to the driving conditions, vehicle speed, and driver preferences.

Electric steering rack belts are highly responsive and can make real-time adjustments to improve stability and control. This is particularly beneficial in emergency situations, where the system can provide additional assistance to help the driver regain control of the vehicle.

Types of Electric Steering Rack Belts

The term "electric steering rack belt" encompasses various designs and technologies used in modern vehicles. Different types of electric steering systems are employed to meet specific performance requirements and market demands. Here are the main types of electric steering rack belts:

1. Column-Mounted Electric Power Steering (C-EPS):

Column-mounted electric power steering is a common type of electric steering system, where the electric motor is mounted on the steering column itself. This design provides a direct connection between the driver's steering input and the assistance provided by the motor, resulting in precise and responsive steering.

2. Rack-Mounted Electric Power Steering (R-EPS):

In rack-mounted electric power steering systems, the electric motor is attached to the steering rack. This design offers benefits such as reduced weight and complexity in the steering column. It is often used in smaller vehicles where space is limited and in midsize to full-size vehicles where the system's weight savings can contribute to improved fuel efficiency.

3. Pinion-Assist Electric Power Steering (P-EPS):

Pinion-assist electric power steering is a variation of R-EPS. In this design, the electric motor is connected to the steering pinion, which meshes with the steering rack. This arrangement provides a balance between precise control and energy efficiency.

4. Direct Drive Electric Power Steering (D-EPS):

Direct drive electric power steering eliminates the need for a belt or gear to connect the motor to the steering components. Instead, it directly drives the steering rack. This design minimizes power losses and can enhance system response.

The Role of Sensors in Electric Steering Rack Belts

Sensors are integral to the operation of electric steering rack belts. They continuously monitor various parameters to ensure that the system responds appropriately to the driver's input and road conditions. Key sensors used in electric steering systems include:

1. Torque Sensor:

The torque sensor measures the force applied to the steering wheel. By detecting the driver's steering effort, it helps the system determine the level of assistance required.

2. Position Sensor:

Position sensors track the position of the steering wheel. They provide essential feedback to the electric motor, enabling it to align the front wheels accurately with the driver's input.

3. Vehicle Speed Sensor:

Vehicle speed sensors gauge the vehicle's speed, allowing the system to adjust the level of assistance. At higher speeds, less assistance is needed, whereas more assistance may be required at lower speeds for ease of maneuvering.

4. Load Sensor:

Load sensors assess the resistance encountered by the steering system, such as when driving over uneven road surfaces or when parking. They help optimize the assistance provided by the electric motor.

5. Yaw Rate Sensor:

Yaw rate sensors detect the vehicle's rotational movement, helping the system improve stability by making steering adjustments to prevent skidding or oversteer.

Electric Steering Rack Belts and Autonomous Driving

The advent of autonomous driving technology has had a significant impact on the development of electric steering rack belts. Autonomous vehicles require highly reliable and adaptable steering systems to operate safely. Electric steering systems, equipped with advanced sensors and control algorithms, play a pivotal role in achieving this.

Here's how electric steering rack belts contribute to autonomous driving:

1. Precise Control:

Electric steering systems can provide precise control over the vehicle's steering, enabling autonomous vehicles to navigate complex environments with accuracy.

2. Integration with ADAS:

Electric steering systems seamlessly integrate with advanced driver assistance systems (ADAS), which are essential for autonomous driving. These systems rely on accurate steering control to execute functions such as lane-keeping, adaptive cruise control, and automated parking.

3. Redundancy and Safety:

Autonomous vehicles require redundant systems to ensure safety. Electric steering rack belts, with their advanced sensor technology and fault-tolerant design, can contribute to the redundancy required for autonomous driving.

4. Adaptability:

Autonomous vehicles encounter a wide range of road conditions and scenarios. Electric steering systems can adapt to different driving conditions, making them well-suited for autonomous vehicles that need to handle diverse situations.

5. Data Integration:

Electric steering systems can collect and transmit valuable data about the vehicle's steering behavior. This data can be used for real-time analysis and decision-making in autonomous driving systems.

Challenges and Considerations

While electric steering rack belts offer numerous advantages, there are also some challenges and considerations associated with their use:

1. Reliability:

Electric steering systems are highly reliant on electrical components and sensors. Ensuring their long-term reliability is crucial for the safety and performance of a vehicle.

2. Complexity:

The integration of electric steering systems with other vehicle systems, such as ADAS and autonomous driving features, adds complexity to the vehicle's electronics. This complexity requires robust software and hardware design.

3. Driver Feedback:

Some drivers may prefer the tactile feedback provided by traditional hydraulic power steering systems. Electric systems need to be carefully tuned to provide an acceptable level of feedback to the driver.

4. Electrical Power:

Electric steering systems depend on electrical power. Ensuring a stable power supply is essential to prevent system failure.

5. Cost:

While electric steering systems offer many benefits, the initial cost of implementing these systems can be higher compared to traditional hydraulic systems.

The Future of Electric Steering Rack Belts

Electric steering rack belts have rapidly become a staple in the automotive industry, and their role will continue to evolve in the coming years. The future of electric steering rack belts is likely to be characterized by:

1. Enhanced Autonomous Driving Capabilities:

As autonomous driving technology advances, electric steering systems will play an increasingly critical role in providing the precise and adaptive steering control necessary for self-driving vehicles.

2. Energy Efficiency:

Efforts to improve the energy efficiency of electric steering systems will continue. This includes the development of more efficient electric motors and power management systems.

3. Customization:

Manufacturers will focus on offering customizable steering experiences to cater to individual driver preferences and regional driving conditions.

4. Sustainability:

The automotive industry is moving towards sustainability, and electric steering systems will play a part in reducing the environmental impact of vehicles by minimizing power losses and energy consumption.

5. Redundancy and Safety:

With the increasing use of electric steering in autonomous vehicles, there will be a growing emphasis on redundancy and safety measures to ensure the reliability of steering control in all conditions.

In Conclusion

The steering rack belt, especially in its electric form, represents a remarkable advancement in automotive technology. It has transformed the way we steer vehicles, providing benefits such as improved fuel efficiency, reduced maintenance, and adaptability. The integration of electric steering rack belts with autonomous driving systems further demonstrates their significance in the automotive landscape.

As the automotive industry continues to innovate, electric steering rack belts will remain a critical component, shaping the future of steering and vehicle control. With their capacity to provide precise and adaptive steering assistance, electric steering systems will play a pivotal role in realizing the potential of autonomous driving and more sustainable, efficient, and driver-friendly vehicles.

The Previous Articles:

What Is Rack and Pinion Bushing? How To Tell If Rack and Pinion Bushings Are Bad?

Why Steering Rack Makes Noise When Turning?

How To Rebuild A Steering Rack?

What Is A Rotary Valve Power Steering Rack?

Rack And Pinion System Vs Power Steering System: What Are The Differences?

Power Steering Rack Market Analysis Report (Japan Market)

What Causes Steering Rack to Go Bad?

Design Of Car Rack And Pinion Steering Racks

What Is The Intelligent Steering Rack Used By VW, Toyota, Honda And Renault?

Understanding Steering Angle Sensors: A Detailed Overview

Demystifying Power Steering Fluid: Understanding Its Role in Steering Systems

What is steering rack repair kit?

What is power steering reservoirs?

Understanding the Severity of Rack and Pinion Leaks in Your Vehicle

How to Find a Reliable Supplier of Steering Rack in China? Why You Should Choose Us?

What Is a Steering Rack Belt: Exploring the Role of Electric Steering Rack Belts

What Causes Drive Shaft Failure?

Steering Rack: When Should You Replace It?

Is Steering Rack Expensive to Fix? Exploring Steering Rack Repair and Costs

Demystifying the Difference Between Steering Rack and Steering Column

Leave A Comment