In the process of driving a car, the driver needs to change the driving direction frequently according to the road condition, so for wheeled cars, the steering system can make the wheels connected with the steering axle deflect a certain angle relative to the longitudinal axis of the car, so as to realize the vehicle steering.

According to the different steering power, the steering system is divided into mechanical steering system and power steering system. Currently, power steering systems are used in automobiles, and power steering systems can be divided rack into hydraulic steering systems and electric steering systems.

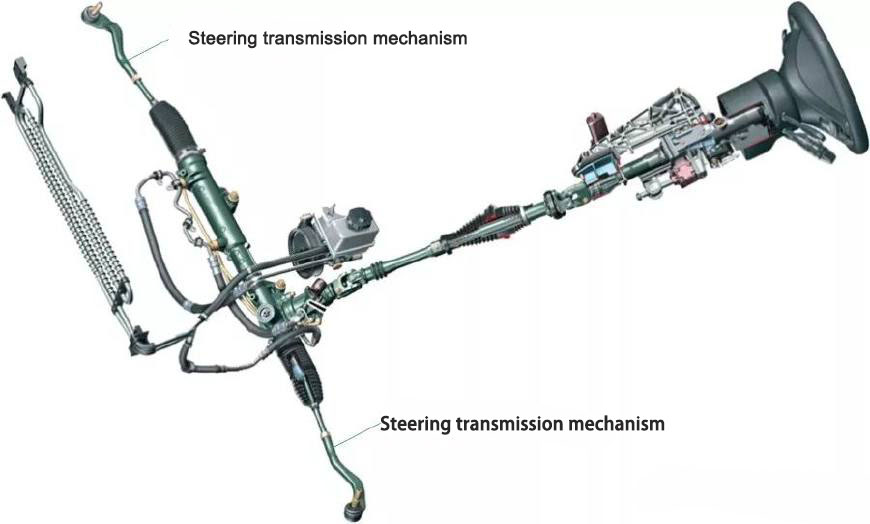

The steering system usually consists of a steering manipulator, steering rack, and steering transmission mechanism.

1 Steering Manipulator

The steering mechanism mainly includes the steering wheel and the steering column.

01. Steering Wheel

The steering wheel is round in shape, and its main function is to transfer the torque applied by the driver to the steering wheel to the steering column. Its interior is composed of a metal frame, and the outer edge is wrapped with soft synthetic rubber or resin to play a cushioning role.

02. Steering Column

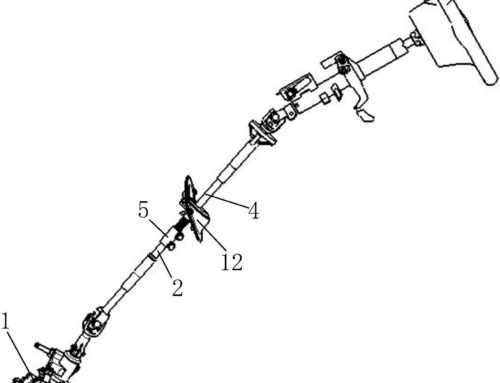

The steering column is located between the steering wheel and the steering wheel, and its main function is to transmit the steering torque from the steering wheel to the steering gear. The steering column is mainly composed of a steering column tube, steering shaft, steering drive shaft, universal joint, steering column adjustment mechanism, etc.

2 Steering rack diagram

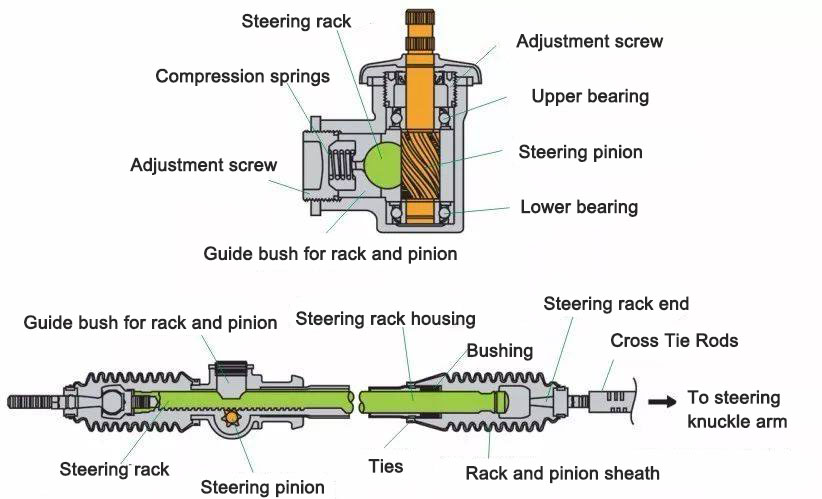

The steering gear is the reduction transmission device of the steering system. The steering gears widely used in automobiles are rack and pinion type and recirculating ball type.

01. Rack and pinion type

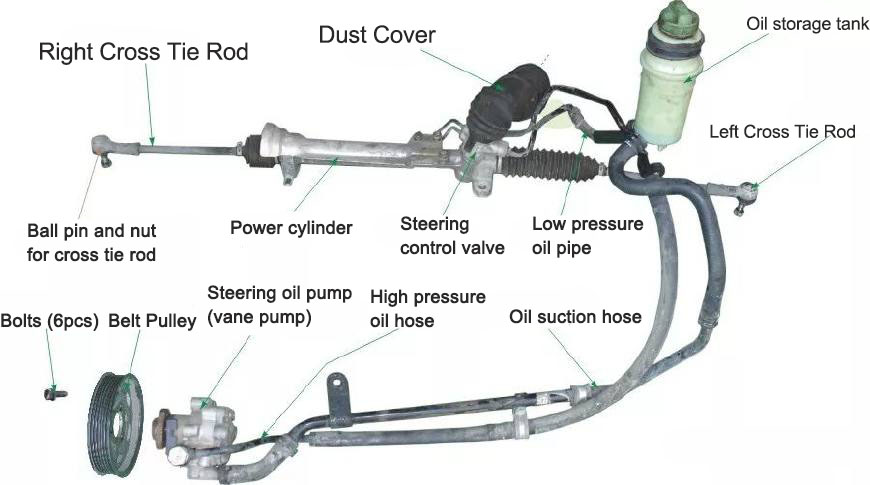

Rack and pinion steering gears are usually mounted on the subframe or engine bracket, and the mounting points are rubber padded to isolate vibration and shock. Rack and pinion steering gears are widely used in small buses and light vehicles because of their simple structure, small mass, sensitive steering, low cost, and easy arrangement. The rack and pinion steering gear is mainly composed of an input shaft, pinion, rack, steering housing, etc.

02. Recirculating ball type

Recirculating ball-type steering gear generally has two stages of transmission, the first stage adopts screw and nut transmission, and the second stage adopts fan and rack transmission. Circulating ball steering gears have high transmission efficiency, light handling, long service life, smooth and reliable operation, and are usually used in trucks or off-road vehicles. Circulating ball steering gear is mainly composed of an input shaft, steering screw, steering nut, steel ball, steel ball duct, gear fan shaft (rocker arm shaft), steering gear housing, etc.

3. Steering transmission mechanism

The steering transmission mechanism transmits the torque output from the steering gear to the steering knuckles on both sides of the steering axle to deflect the steering wheels on both sides. At the same time, it makes both sides of the steering wheel deflection angle change according to a certain relationship, in order to ensure that the relative sliding of the wheels and the ground when the car is steering is as small as possible.

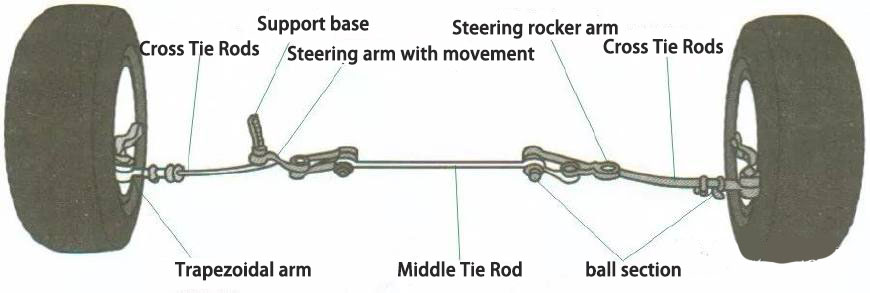

There are two types of steering transmission mechanisms: tie rod type and parallel type.

01. Tie rod type steering transmission mechanism

The tie rod type steering transmission mechanism is used with the rack and pinion type steering gear, which is mainly composed of a cross tie rod, trapezoidal arm, and the steering knuckle (ball joint). When the rack and pinion move from side to side, the cross tie rod moves equally to push the trapezoidal arm and steering knuckle to rotate around the pivot point, thus deflecting the steering wheel by the corresponding angle. The cross-tie bar is composed of inner and outer cross tie bars. The ball joint mainly consists of the ball head, ball head pin, ball head seat, ball joint nest, compression spring, dust cover, etc.

02. Parallel steering transmission mechanism

The parallel steering transmission mechanism is used in conjunction with the recirculating ball steering, which is mainly composed of a steering rocker arm, intermediate tie rod, cross tie rod, trapezoidal arm, follow-on steering arm, and support seat, ball joint, and so on. Some luxury cars or off-road cars have a damping damper installed in the parallel steering transmission mechanism to absorb the vibration transmitted by the steering wheel. When steering, the rocker arm shaft of the steering gear drives the rocker arm to swing and the middle tie rod to move, thus driving the left and right cross tie rod to move laterally and pushing the trapezoidal arm and ball joint to turn around the pivot point to realize steering.

Content source.

<The perspective view explains the car structure. Principle and Disassembly>Chemical Industry Press Editor-in-Chief: Yu Haidong

(We do not share your data with anybody, and only use it for its intended purpose)

The Previous Articles:

What Is Rack and Pinion Bushing? How To Tell If Rack and Pinion Bushings Are Bad?

Why Steering Rack Makes Noise When Turning?

How To Rebuild A Steering Rack?

What Is A Rotary Valve Power Steering Rack?

Rack And Pinion System Vs Power Steering System: What Are The Differences?

Power Steering Rack Market Analysis Report (Japan Market)

What Causes Steering Rack to Go Bad?

Design Of Car Rack And Pinion Steering Racks

What Is The Intelligent Steering Rack Used By VW, Toyota, Honda And Renault?

Nice article, written in great detail!

I am very happy this article can help you!

What a great article! Very helpful for me!

thank you~