There are many things to pay attention to in the daily use of the steering gear, improper operation may lead to a serious failure of the steering system. So, what should we pay attention to in the process of daily use? And how to carry out effective testing? Please see the following contents.

1 Precaution for use

1) Improper use of hydraulic fluid can also cause heavy steering and damage the steering pump.

1, need to use the standard matching anti-wear hydraulic oil.

2, the oil quality must be clean, with no deterioration, and no corrosion.

3, can not use two different types of hydraulic oil at the same time.

Too dirty fluid causes steering failure

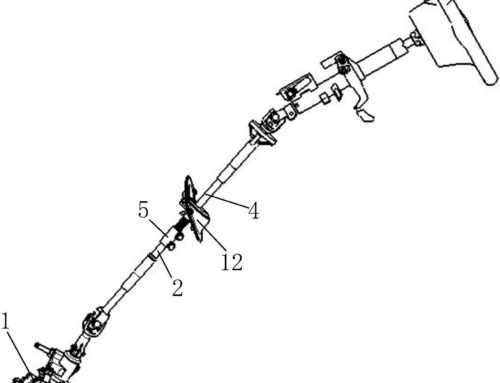

2) The steering pendant arm is assembled with the steering output arm shaft.

When installing the steering gear, pay attention to the mark on the steering pendant arm that must be aligned with the mark on the steering output arm shaft.

The markings must be aligned during assembly, otherwise, it will cause unilateral under-turning.

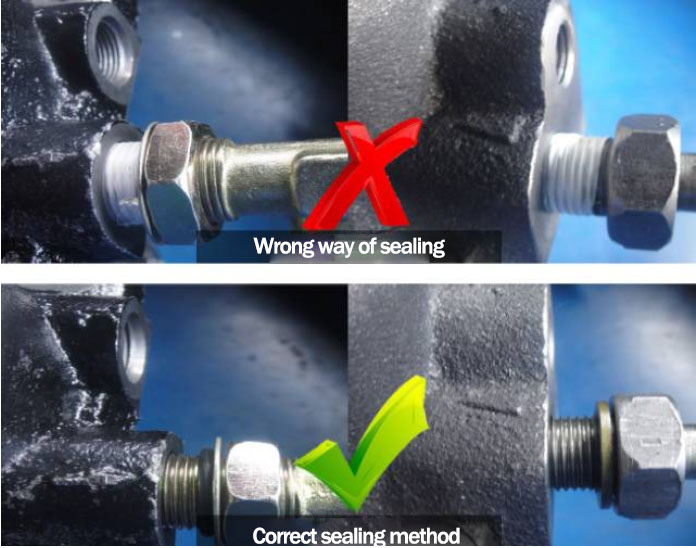

3) Forbidden to use raw material tape seal

4) Other notes

1、Make sure the steering transmission parts (between the steering rack and bracket, steering gear bracket and beam, steering pendant arm and steering gear output, ball pin, and steering pendant arm) are tight and reliable, otherwise, the vehicle will cause drifting and snaking phenomenon when driving.

2, the steering rack has been adjusted to the best condition before leaving the factory, no need to adjust the vehicle can be installed and used, equipped with automatic adjustment of travel unloading valve assembly, due to the factory preset total number of turns 4.5 turns, before loading the vehicle shall not be forced to turn the input end more than ± 2.25 turns, after loading the vehicle according to the actual needs of the corner forced to turn the steering wheel to the required limit position, to reach the automatic limit.

3、Try to avoid turning the steering wheel to the limit position during use, and pause in the limit position should not exceed 30 seconds.

4, the steering gear in and out of the oil port can not be connected to the opposite (into the oil port logo arrow facing inward, out of the oil port logo arrow facing outward), otherwise, it will not only cause the hand phenomenon, can not be normal steering and will cause the upper cover low-pressure oil seal is high pressure wash out, causing oil leakage.

2 Common Failure Modes

1) Failure caused by improper matching of steering gear & steering pump or overload use.

1, improper selection of steering gear causes the long-term high temperature of the system, making the hydraulic oil carbonized, causing heavy steering and leakage due to the failure of the internal seals of the steering gear.

2, when the vehicle is overloaded, the steering pump works under high pressure for a long time, which leads to the system oil temperature rising, easily causing the early failure of the steering pump and eventually leading to heavy steering.

Hydraulic oil carbonization

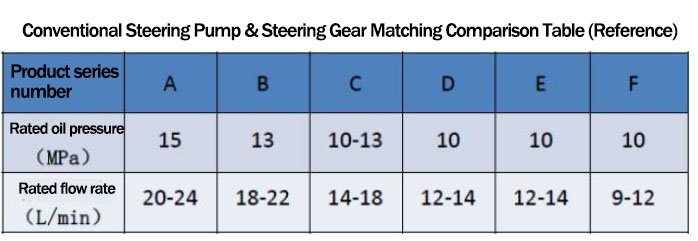

3, The oil pump selected requires stable rated oil pressure and flow rate to meet the fast steering needs of the car steering.

Note: When the steering gear is used for double axle steering, the flow rate of the steering oil pump needs to be increased appropriately according to the size of the cylinder because a cylinder is connected in parallel to the hydraulic circuit.

2) Failure is often caused by a lack of oil or dirty hydraulic oil.

When the hydraulic oil is missing, it will reduce the amount of hydraulic oil flowing to the working chamber of the power steering, making it difficult to establish a large oil pressure difference and making the steering heavy; it will also appear that the amount of hydraulic oil flowing through the working chamber is different, thus causing the lightness of the left and right steering to be different.

Dirty hydraulic oil, impurities in the oil may block the oil circuit, slow down the flow rate of the whole hydraulic system, reduce the oil pressure difference, and cause heavy steering. Dirty hydraulic oil will also block the movement of the steering control valve, making the power steering work less effective or even fail.

3) Failure caused by air in the steering hydraulic system.

The power steering system itself is a closed high-pressure circulation system, hydraulic oil in the oil pump, oil storage tank and power steering circulating back and forth between the working pressure range of 7 MPa ~ 10 MPa, the air in the system blocked the smooth flow of hydraulic oil, so that the power steering upper and lower cavity oil volume or oil pressure is reduced, resulting in heavy steering, left and right steering weight and driving front-wheel swing head.

3 Steering gear and steering pump failure identification

1) Test the steering valve for internal leakage?

1, Connect the testing equipment under the condition of ensuring the steering pump is normal so that the control valve is on.

2, Install the special limit bolt to ensure that the steering angle is rotated within ±35°.

3, Start the engine and keep it running at idle speed.

4, respectively, to the left and right to beat the direction, observe the pressure gauge value.

Left limit.

P measurement ≥ 0.85 * P rated pressure (MPa), can be judged to turn the valve normal.

P measurement < 0.85 * P rated pressure (MPa), can be determined that the internal leakage of the rotary valve.

Right limit.

If P measurement is ≥0.85*P rated pressure (MPa), the valve is judged to be normal.

If P measurement < 0.85*P rated pressure (MPa), it can be judged that the valve is leaking.

2) Detect whether the steering pump is damaged?

1, Connect the testing equipment so that the control valve is on.

2, Start the engine and keep it idling.

3, close the control valve (clockwise rotation, stay no longer than 5 seconds), and observe the pressure gauge value.

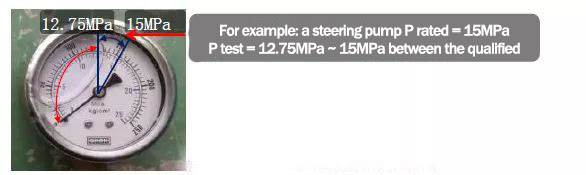

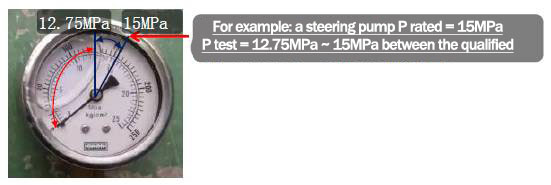

P measurement ≥ 0.85 * P rated pressure (MPa), the steering pump can be judged normal.

If P measurement <0.85*P rated pressure (MPa), the steering pump can be judged to be damaged.

If the pressure gauge pointer does not respond or the pressure gauge pointer wavers, the steering pump can be judged to be damaged.

3) Check whether the hydraulic fluid is blocked?

When the steering pump and steering gear are normal, the steering system still has high temperature and heavy steering, then we should check when the control valve is on.

1, Observe the pressure gauge value at idle speed.

Normal: P test = 0.1-0.3MPa or less

Abnormal: P test > 0.5MPa

2, Increase the throttle to the engine at 1500r/min and observe the pressure gauge value.

Normal: P test = 0.2-0.4MPa or less

Abnormal: P test > 0.8MPa

3, Increase the throttle to the engine at 2000r/min-3000r/min and observe the value of the pressure gauge.

Normal: P measurement = 0.5MPa or less

Abnormal: P test>1MPa

Note: The resistance value is not within the range of a part of the steering system is clogged, must be investigated to replace the joints, oil pipe, filter and steering runner and solve the problem.

(We do not share your data with anybody, and only use it for its intended purpose)

The Previous Articles:

What Is Rack and Pinion Bushing? How To Tell If Rack and Pinion Bushings Are Bad?

Why Steering Rack Makes Noise When Turning?

How To Rebuild A Steering Rack?

What Is A Rotary Valve Power Steering Rack?

Rack And Pinion System Vs Power Steering System: What Are The Differences?

Power Steering Rack Market Analysis Report (Japan Market)

What Causes Steering Rack to Go Bad?

Design Of Car Rack And Pinion Steering Racks

What Is The Intelligent Steering Rack Used By VW, Toyota, Honda And Renault?

Leave A Comment